Understanding Metal Tolerances in Fabrication

In Focus

In metal fabrication, precision matters. A small variation can determine whether a part fits seamlessly into an assembly—or ends up scrapped.

That’s where metal fabrication tolerances come in. Defined as the allowable deviation from a specified dimension, tolerance ensures consistency, quality, and performance in every finished product.

What Is Metal Tolerance?

Tolerances appear on blueprints or shop drawings and establish the acceptable range of variation for dimensions like hole size, edge cuts, and bends. As Matthew Stelzer, Inside Sales Manager for Ryerson Advanced Processing, explains:

“The tolerances are critical for how the parts fit together with other parts. If the dimension on the cut piece is too far above or too far under the allowable deviation, the part’s no good and cannot be shipped to the customer”.

Tolerances can be expressed in decimals or fractions, in either inches or millimeters. They are often listed in the title block of a drawing, which acts as the roadmap for how a part should be fabricated.

Why Tolerance Matters in Metal Fabrication

- Fit and Function: Meeting tolerances ensures assemblies line up as designed. A hole that’s just 0.010” too small may prevent a bolt from fitting, while a slightly oversized slot can reduce structural stability.

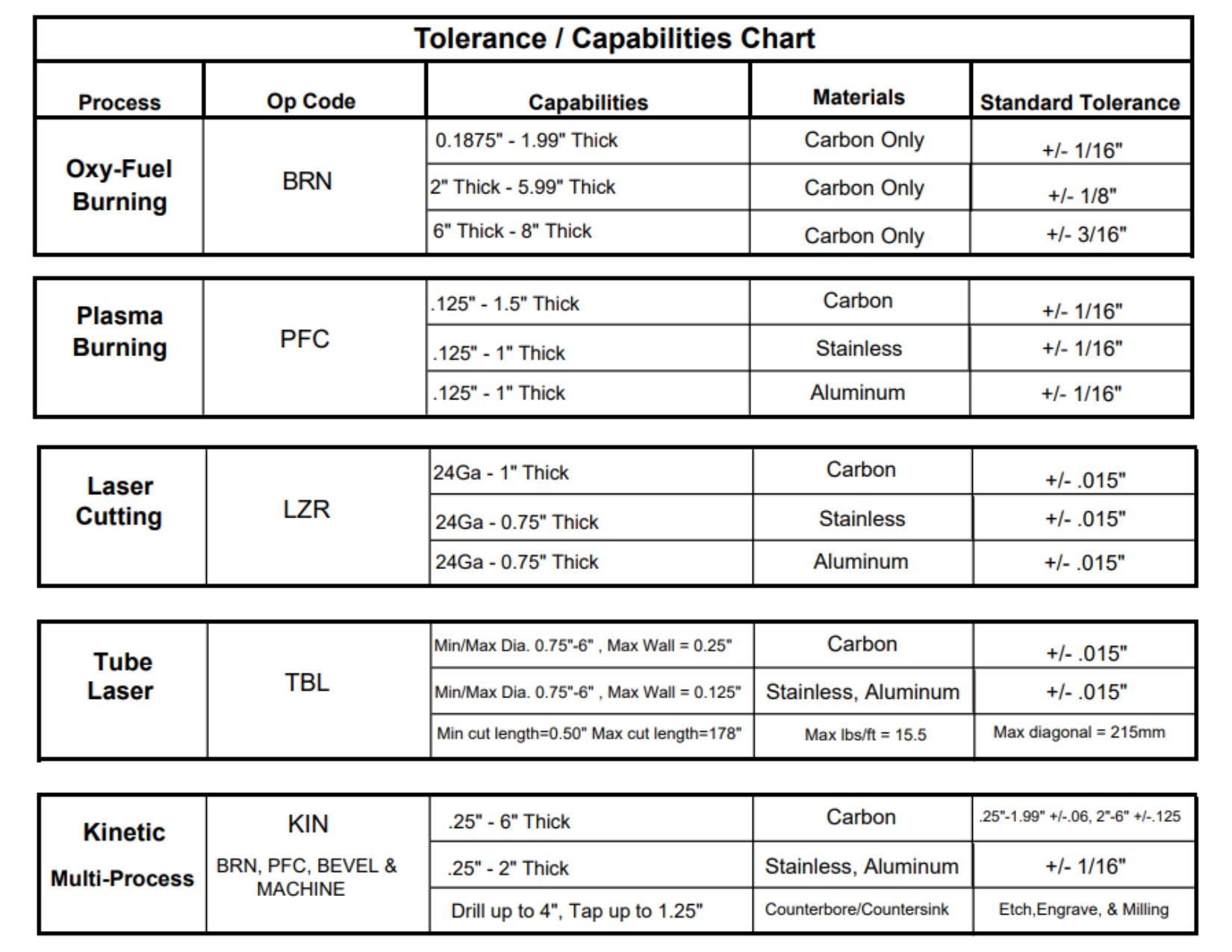

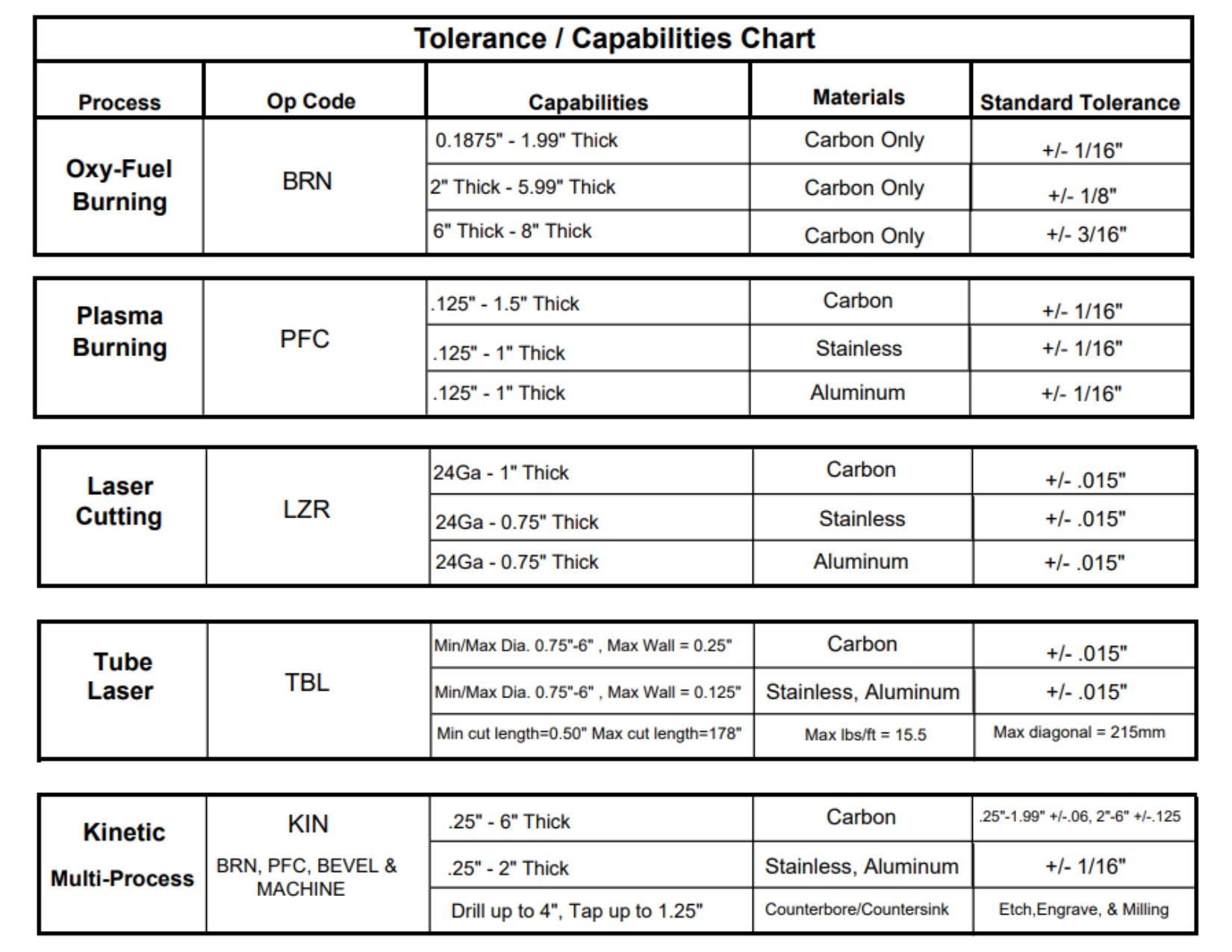

- Process Selection: Tighter tolerances may require precision processes like laser cutting, while looser tolerances might be achieved more cost-effectively with plasma cutting or oxy-fuel cutting.

- Efficiency and Cost: Striking the right balance between fabrication accuracy and cost helps avoid overspending on precision that isn’t necessary for the application.

Matching Fabrication Process to Tolerance

Every cutting method has its own level of accuracy:

- Laser Cutting Tolerances: Lasers can achieve tight tolerances (±0.005”), making them ideal for parts with small holes, intricate profiles, or slot-and-tab designs.

- Plasma Cutting Accuracy: Plasma typically holds tolerances around ±0.063”. It’s a cost-effective option for thicker materials but not suited for very tight hole or corner requirements.

- Oxy-Fuel Cutting: Capable of cutting plate 20”+ thick, though tolerances are looser compared to laser or plasma.

- Waterjet Cutting Tolerances: Provides precision without a heat-affected zone, making it valuable when material integrity must be preserved.

“Part tolerances can be matched to machine process tolerances that are best suited for producing the part on the drawing,” Stelzer adds.

How Tolerances Are Checked

Meeting tolerances isn’t just about cutting methods—it’s also about quality control in fabrication. Tools commonly used to measure tolerance include:

- Calipers: Precision to ±0.001”, perfect for standard dimensions.

- Digital Protractors: Measure bends and angles within 0.1°.

- 3D Laser Scanners: Compare fabricated parts to CAD models, identifying even the smallest deviations.

The Bottom Line

Metal tolerances for fabrication aren’t just technical details—they dictate how parts are produced, which processes are chosen, and whether the final assembly performs as intended. By aligning tolerances with the right fabrication method, manufacturers can ensure accuracy, improve efficiency, and avoid costly errors.

As Stelzer says, “The drawing file provides us with the instructions on how to manufacture the part. The CAD files provide accuracy and speed. But the title block contains the tolerances that make sure the part is made correctly”.

Connect with a Metal Fab Pro Today!